The turbo pump passed the medium test assessment

- Categories:News Center

- Time of issue:2020-07-07 15:17

(Summary description)In early January 2019, the core component of the Kyushu Yunjian "Lingyun" engine (12 tons thrust)-the coaxial turbopump completed the low-temperature medium test assessment. This test assessed the design accuracy of the gap between the turbopump and the static part, seals, and bearings. And the adaptability of the axial force design to multiple working conditions, the main parameters of the turbopump performance parts were obtained. During the test, the turbopump speed, pressure, and temperature curves were stable. After the test, a series of inspection results of the turbopump were normal and reached the test. The purpose of the assessment.

The turbo pump passed the medium test assessment

(Summary description)In early January 2019, the core component of the Kyushu Yunjian "Lingyun" engine (12 tons thrust)-the coaxial turbopump completed the low-temperature medium test assessment. This test assessed the design accuracy of the gap between the turbopump and the static part, seals, and bearings. And the adaptability of the axial force design to multiple working conditions, the main parameters of the turbopump performance parts were obtained. During the test, the turbopump speed, pressure, and temperature curves were stable. After the test, a series of inspection results of the turbopump were normal and reached the test. The purpose of the assessment.

- Categories:News Center

- Time of issue:2020-07-07 15:17

- Views:

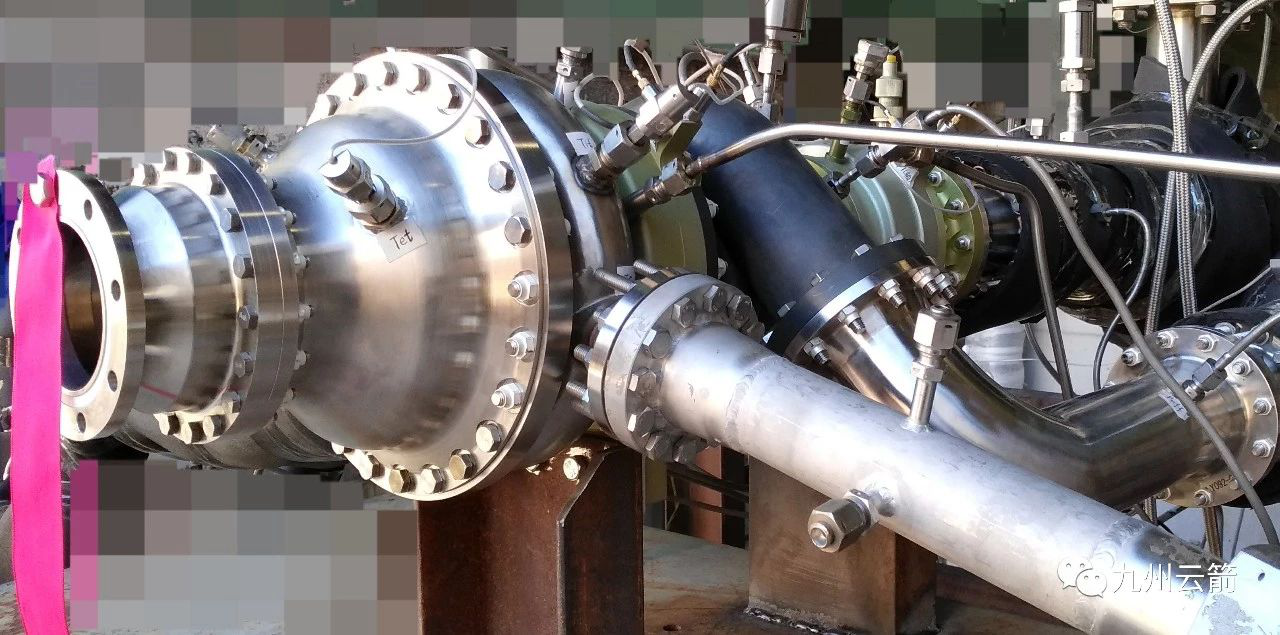

In early January 2019, the core component of the Kyushu Yunjian "Lingyun" engine (12 tons thrust)-the coaxial turbopump completed the low-temperature medium test assessment. This test assessed the design accuracy of the gap between the turbopump and the static part, seals, and bearings. And the adaptability of the axial force design to multiple working conditions, the main parameters of the turbopump performance parts were obtained. During the test, the turbopump speed, pressure, and temperature curves were stable. After the test, a series of inspection results of the turbopump were normal and reached the test. The purpose of the assessment.

This test is of great significance. The Lingyun engine turbopump is the first turbopump designed and manufactured in the domestic commercial aerospace market and passed the assessment. The success of this test has ended the previous domestic commercial aerospace liquid rocket engine stage with a full bloom of combustion devices. There has never been a situation where high-speed rotating machinery appeared on stage. So far, all the main components of the Kyushu Yunjian Lingyun engine: igniter, gas generator, thrust chamber, turbo pump, main and auxiliary system valves and thrust regulating devices have all completed component-level tests.

There is a general consensus in the field of fluid power: "Those who get the engine get the rocket, and those who get the turbopump get the engine." As the heart of the liquid rocket engine, the turbopump is the only high-speed rotating machine in the main assembly of the engine. It is responsible for pressurizing the low-pressure propellant in the rocket tank and delivering it to the thrust chamber and auxiliary system for combustion to produce gas in real time. , The important task of recommending the launch vehicle to get rid of the gravity of the planet. Do not underestimate the function of "supercharging". In order to achieve the excellent performance of the engine's overall technical parameters, the turbo pump must complete the supercharging task under many strict restrictions. The temperature and pressure of the inlet of the pump and the turbine are limited, and the flow rate is limited. Restrictions and weight constraints, coupled with a harsher temperature and vibration environment, will eventually have to be able to hit a higher head. It can be said that the turbo pump designer is a craftsman "dancing in shackles". Under strict constraints, designers must solve a series of problems such as pumps, turbines, rotor dynamics, seals, bearings, axial force balance, heat transfer, structural statics/dynamics, materials, manufacturing processes, etc. It is possible to build a good turbo pump.

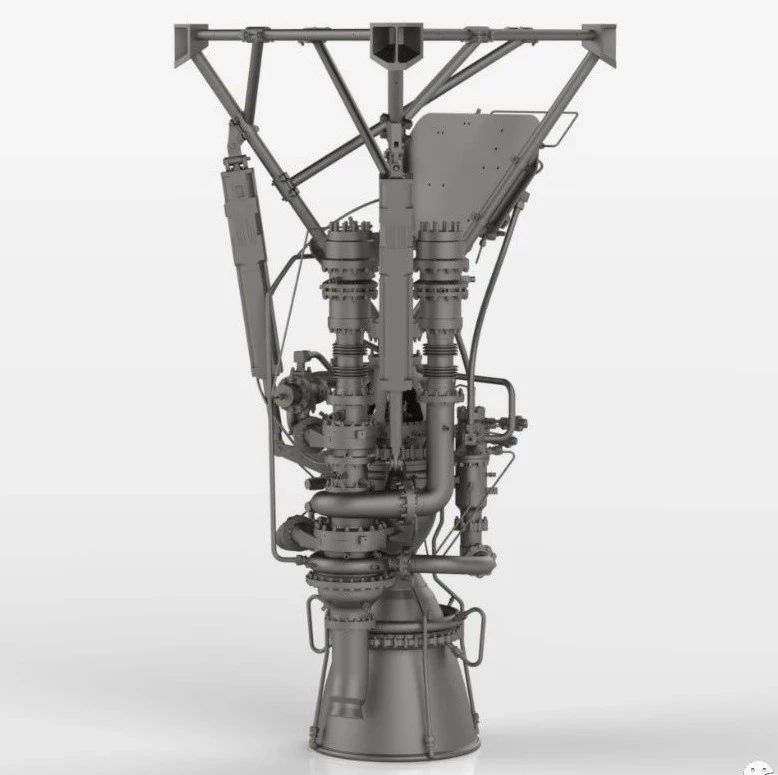

The Lingyun engine turbopump used commercial aerospace engines and commercial transportation as the main application scenarios during the program demonstration. Under the premise that the physical parameters of liquid oxygen/methane were relatively close, reliability, cost, weight and other factors were comprehensively considered, and finally the same was established. Big scheme of shaft turbo pump. Compared with the oxidizer/fuel dual turbo pump, the coaxial turbo pump can reduce the number of components, reduce the weight of the turbo pump, and improve reliability. Lingyun engine uses a liquid oxygen/methane dual cryogenic propellant combination. The pump end temperature is as low as minus 190°C, and the driving gas temperature of the turbine end auxiliary system is as high as 700°C or more. In such an environment of ice and fire, the turbo pump Running at a high speed of tens of thousands of revolutions per minute, the physical property changes and structural changes of different materials at low temperature, high temperature and large temperature gradients are also carefully considered and strictly controlled during the design and manufacturing of the turbopump.

In order to reduce the structural weight as much as possible, in the design process of the Lingyun engine turbopump, every internal structural detail was carefully considered, and innovations were made on the basis of existing experience. After multiple rounds of iterations, the Lingyun 1MW was finally developed. The structural weight of the turbo pump with the above power is controlled at the level of 31kg. The power density ratio of the turbo pump has reached 33kw/kg, which is a very difficult technical indicator for a 10t-class engine. Under the same thrust level, the increase in the power density of the turbo pump can significantly reduce the weight of the engine. Improve the carrying capacity of the customer's carrier system, which is in line with the needs of the commercial aerospace market.

Over the past year, Kyushu people have forged ahead on the road of commercial liquid engine development. Kyushu Yunjian Lingyun engine turbo pump completed the program demonstration in April 2018, the detailed design was completed at the end of May, the tooling tool design was completed in June, and the comprehensive design was completed in July. It was put into production, and the turbo pump products were all set in November, and the turbo pump assembly was completed in early December. After completing the medium test, this turbopump will continue to participate in the joint test of the auxiliary system and the hot test of the engine to further assess the adaptability of the turbopump to the engine's deep variable thrust, as well as the work matching and reliability of each assembly. In the future, the people of Kyushu will continue to carry forward the spirit of struggle and innovation in China's aerospace industry, immerse themselves in their hard work, give full play to their strengths, and strive to become a liquid power company that serves the global commercial aerospace market, becoming a useful supplement to China's aerospace industry and contributing to human exploration of space Contribute out of China.

Scan the QR code to read on your phone

Contact Us

Add: 2nd Floor, Building 32, No. 109, Jinghai 3rd Road, Beijing Economic and Technological Development Zone

Phone: 010-67948968 / 9

Email: zhaopin@jzyjspace.com

Follow us