Thrust adjustment system media test, nozzle passed the suppression test

- Categories:News Center

- Time of issue:2020-07-07 14:43

(Summary description)In March 2019, Kyushu Yunjian ①The thrust adjustment system completed the medium test assessment, ②The thrust chamber nozzle passed the suppression test assessment, and the development of Lingyun engine took another solid step.

Thrust adjustment system media test, nozzle passed the suppression test

(Summary description)In March 2019, Kyushu Yunjian ①The thrust adjustment system completed the medium test assessment, ②The thrust chamber nozzle passed the suppression test assessment, and the development of Lingyun engine took another solid step.

- Categories:News Center

- Time of issue:2020-07-07 14:43

- Views:

In March 2019, Kyushu Yunjian ①The thrust adjustment system completed the medium test assessment, ②The thrust chamber nozzle passed the suppression test assessment, and the development of Lingyun engine took another solid step.

A major prerequisite for liquid rocket engines to be suitable for use in the commercial aerospace market is to have recycling and reuse capabilities. Through recycling and reuse, the launch cost can be reduced step by step, so that commercial applications can be gradually realized. At the beginning of the design of Lingyun engine, it aimed at the commercial aerospace demand of recyclable and reusable. After full demonstration, the thrust adjustment range of Lingyun engine was determined to be 30%~100%. The key to achieve large-scale adjustment of thrust is the thrust control valve system. Through the stepless adjustment of valve opening, the medium flow control of the engine is realized, so that the engine can change the thrust arbitrarily within the range of 30% to 100% to achieve the rocket's Recycling, it can be said that the thrust regulating valve and regulating technology of the pumped liquid rocket engine is definitely a black technology.

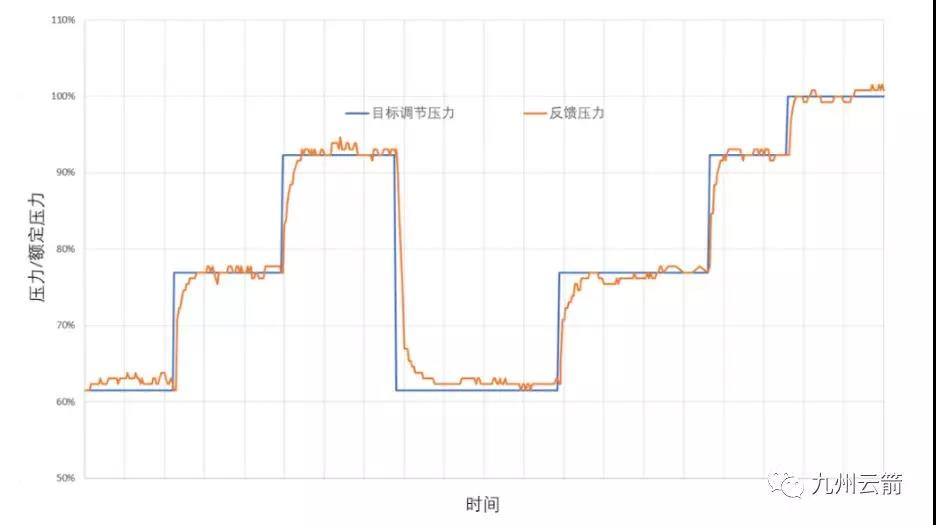

This test evaluated the control characteristics, flow characteristics and control logic of the thrust control valve, and fully verified the rationality of the design scheme, the adaptability of the variable thrust control logic, and the matching of the controller measurement acquisition system Sex. The thrust adjustment system successfully passed the medium test assessment, marking that Kyushu Yunjian has independently broken through another key link in the engine thrust depth adjustment. In the follow-up, the thrust adjustment control logic will be continuously optimized and improved, and the reliability of the thrust adjustment system will continue to be assessed by means of hardware-in-the-loop simulation, medium test, etc., in order to minimize the potential technical risks brought by the variable thrust system to the engine.

Medium test pressure closed loop adjustment curve

The function of the liquid rocket engine nozzle is to expel the high-temperature and high-pressure gas after expansion and acceleration, thereby generating a reaction force, which is the last link of the engine to generate thrust. In order to reduce the manufacturing difficulty in engineering, the thrust chamber structure is generally divided into two parts at the downstream of the thrust chamber throat (the expansion area ratio is 5~8): short nozzle thrust chamber + nozzle extension section, two parts of the structure can be welded Or flange connection.

In order to improve the technical adaptability in the commercial aerospace market, the nozzle extension section of the Kyushu Yunjian Lingyun engine has undergone detailed investigation and demonstration at the plan stage, and it is determined to adopt a double-layer structure with inner and outer walls. This plan can be larger than the tube-bundle structure. Reduce manufacturing difficulty and cost, while domestic private enterprises also have the conditions for realization. The extension section of the Lingyun engine nozzle is designed as a regenerative cooling scheme. It adopts a relatively simple and reliable milling groove sandwich welding process. It is connected with the short nozzle thrust chamber by flange, which is conducive to the early rapid iteration of the development. The reliability of the extension section has been fully assessed after full evaluation , And then changed to welding to connect with the thrust chamber to further reduce the weight of the structure. As a new exploration and attempt of Kyushu Yunjian in the private aerospace manufacturing system, the nozzle extension section of the Lingyun engine overcomes a series of difficulties in design and technology during the development process, and finally successfully breaks through the nozzle. Efficient welding process for inner and outer layers. The finished product of Lingyun engine's first nozzle extension successfully passed the pressure test assessment, which proved that the design of Kyushu Yunjian in the large-size thin-walled sandwich welding program is reasonable and feasible, and the manufacturing process is reliable. The subsequent program will be applied to a larger area ratio. The nozzle is being designed and manufactured.

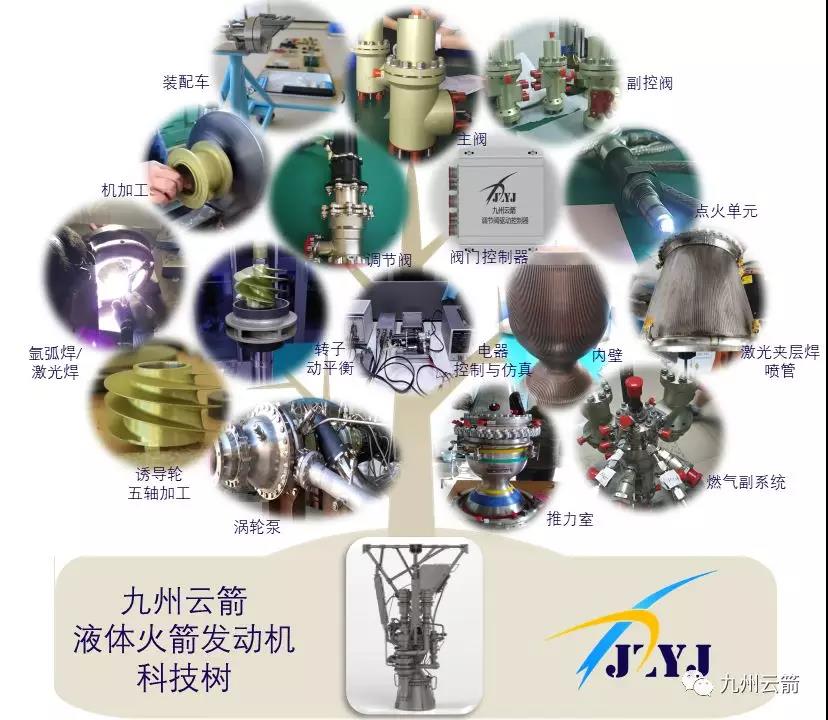

Since the establishment of Kyushu Yunjian for more than a year, Kyushu people have illuminated the tree of liquid oxygen methane rocket engine technology through continuous innovation and practice. We work hard with technology and sweat. We hope that with the continuous efforts of Chinese astronauts, the liquid oxygen methane rocket engine technology tree can continue to absorb nutrients, grow sturdily, root in the fertile soil of military-civilian integration, and bear the fruits of China's commercial aerospace industry. The fruitful fruits.

Scan the QR code to read on your phone

Contact Us

Add: 2nd Floor, Building 32, No. 109, Jinghai 3rd Road, Beijing Economic and Technological Development Zone

Phone: 010-67948968 / 9

Email: zhaopin@jzyjspace.com

Follow us